5. INTRODUCTION 5 Why purification? o Although faucet water is reasonably pure, it is usually variable as a consequence of seasonal variations, regional variation in quality. o 1 ought to take out impurities and Management microbes to stop contamination of products. o Pretreatment will depend on top quality of feed water.

Conditional approval to carry on to the next qualification stage is usually supplied where by specified acceptance criteria or deviation have not been fully resolved and there is a documented assessment that there is no sizeable effect on another exercise.

When all inquiries are actually answered, the documents could be established. In the case of more substantial system initiatives, the generation of a learn qualification system and traceability matrix is necessary while in the pursuits of furnishing a much better overview. The supplier ought to also be capable (in great time).

Water is extensively Employed in the producing course of action at different stages. In the course of manufacturing, water is regularly generated and distributed, which makes it unusable to test and examine every quantity used in production.

If not A part of the document submitted by the vendor pharmaceutical purified water system qualification shall be performed and aspects shall be documented.

This needs to be the exact same good quality of water as used in the similar manufacturing phase (the Preliminary rinse is often purified water)

The principal transform amongst the final Model plus the preceding draft would be the addition of an evaluation of water top quality for the preparation of herbal extracts (where by the water good quality is cross-referenced on the purified water typical).

more than specific timeframe water system website have to be alter & Periodic Re-validation is completed To guage the impact with the change.

At EMMA Intercontinental, we understand the complexities of designing and sustaining WFI systems that meet up with regulatory necessities. Our workforce of professionals can aid with all the things from building WFI systems to making sure ongoing compliance with global pharmacopeia standards.

Calibration Standing: Confirm the calibration position of instruments and units Utilized in the qualification process.

Qualification exercise shall take into account phases from the Original growth with the user prerequisite specification by means of to the end of the usage of the gear, facility, utility, or system.

Compared with validation, revalidation needs much less or no time for checking and observation. In its place, right after any big change revalidation need to commence straight away considering the sensitivity of your pharmaceutical field.

Facility qualification shall be initiated after the protocol for facility qualification is authorized & signed.

This guarantees that activities are executed according to the necessities set within the agreed framework. It is also practical to put in writing down useful specifics of job execution that are not addressed from the URS. This might determine:

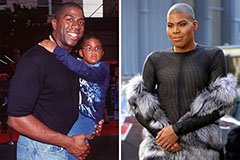

Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Kane Then & Now!

Kane Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!